Modula Plus uses light gauge steel frame technology to engineer walls floors roofs into frame finished components. The studs and joists are rolled on

machines to give high strength galvanised profiles that are then mechanically fixed together to form walls and joist cassettes that whilst strong are easily handled on site.

This same technology is British Research Establishment approved for construction throughout the UK and Europe and indeed the same technology is used throughout the world for residential, commercial and industrial buildings.

Modula Plus can be finished to whatever level the client requires both internally and externally with finishes for any local environment..

This same technology is British Research Establishment approved for construction throughout the UK and Europe and indeed the same technology is used throughout the world for residential, commercial and industrial buildings.

Modula Plus can be finished to whatever level the client requires both internally and externally with finishes for any local environment..

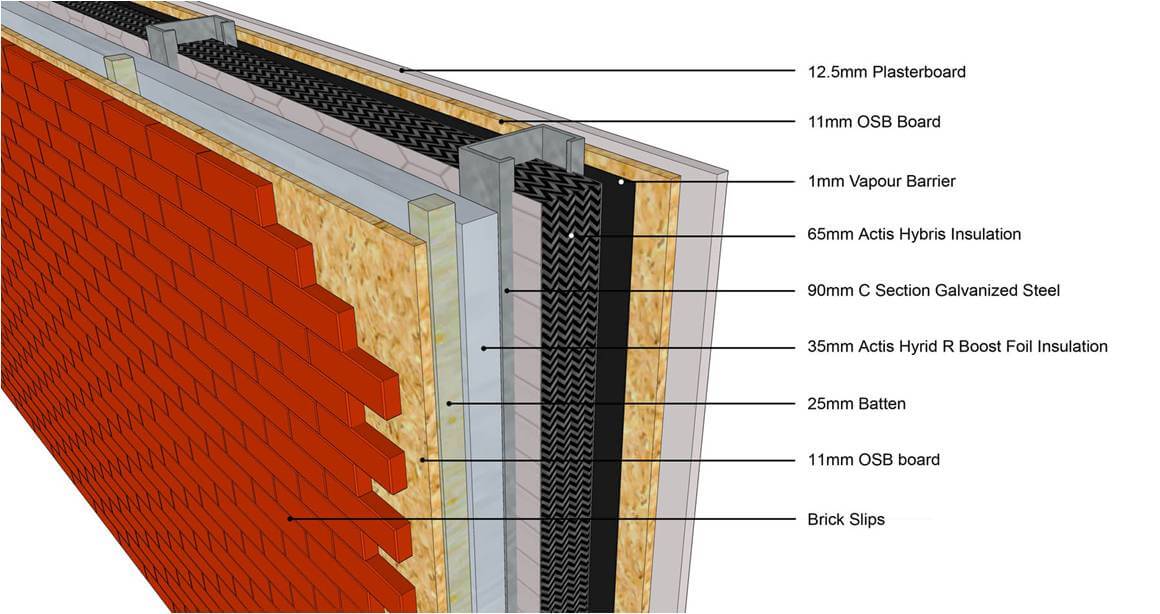

Modula Plus uses light gauge steel frame with a galvanized coating of G275 g/m². Protection from steel corrosion is by sacrificial loss of zinc coating.

No attention is needed at factory cut ends, punched holes or penetrations via self tapping screws or other fixings.

A minimum 60 year design life is expected for most buildings and a design life over 200 years can be achieved with “warm frame” construction

No attention is needed at factory cut ends, punched holes or penetrations via self tapping screws or other fixings.

A minimum 60 year design life is expected for most buildings and a design life over 200 years can be achieved with “warm frame” construction

Modula Plus can have as much insulation as a client requires or a building code requires. The cavity between studs can be filled with mineral fibre insulation and additional rigid insulation can be fitted to the outside as a backing to the final cladding. Can be adapted to suit any U-value required.

The thermal efficiency of the construction ensures that when it is cold outside of the dwelling heat is retained inside the dwelling and when it is hot outside of the dwelling a cool interior can be maintained.

A thermally efficient building reduces running costs of both heating and cooling and also reduces the drain on national power services.

The thermal efficiency of the construction ensures that when it is cold outside of the dwelling heat is retained inside the dwelling and when it is hot outside of the dwelling a cool interior can be maintained.

A thermally efficient building reduces running costs of both heating and cooling and also reduces the drain on national power services.

There are two ways of achieving acoustic separation. One is heavy mass such as bricks and blocks or concrete and the other is having lots of different lightweight layers with different acoustic absorbent properties.

Modula Plus uses lightweight materials designed together to provide the best acoustic separation tailored to the required use of the building. Boards and quilts as well as cavities are combined to give acoustic separation in relatively thin walls compared with masonry walls.

The ability to produce high acoustic values in thinner walls directly translates into lower square area of building and therefore lower overall cost or alternatively for the same cost of building more useable space.

Modula Plus uses lightweight materials designed together to provide the best acoustic separation tailored to the required use of the building. Boards and quilts as well as cavities are combined to give acoustic separation in relatively thin walls compared with masonry walls.

The ability to produce high acoustic values in thinner walls directly translates into lower square area of building and therefore lower overall cost or alternatively for the same cost of building more useable space.

Modula Plus not only uses materials that are none combustible but designs those materials so that in the completed wall or floor combination

they give tested and proven fire separation of spaces.

By using this expertise if in the unfortunate event of a fire starting within the contents of a building the materials of the construction do not add to the conflagration. This not only reduces the potential damage to the structure but also starves the fire of material which in turn allows means of escape routes to remain useable for longer.

The protection of the structure and its integrity not only protects the occupants but also provides greater safety for the fire services when attending a house fire.

By using this expertise if in the unfortunate event of a fire starting within the contents of a building the materials of the construction do not add to the conflagration. This not only reduces the potential damage to the structure but also starves the fire of material which in turn allows means of escape routes to remain useable for longer.

The protection of the structure and its integrity not only protects the occupants but also provides greater safety for the fire services when attending a house fire.

Modula Plus Wall…Example

- This typical wall makeup can be adapted to achieve any U-value a client would wish to achieve.

- The outside finish can be changed to suit a rendered finish or a weatherboard finish.